Disrupting a linear system

BOOMER - RC is intended to explore modularity to minimize types of machinery in the mine, In addition to explore the impact on the workflow of the mine by re-imagining the workshop where these machines get fixed and maintained. The project was done In collaboration with Atlas Copco and New Boliden at The Renström mine in Sweden (1300 meters underground)

Project duration: 4 months / 2012

Opportunity

After being immersed 1300 meters underground to take a close look at the worker’s conditions inside the Renström mine in Sweden, it was clear that the interdependency of performance of the machines, navigation inside the mine, space in the workshop and maintenance of specific parts had a huge impact on the efficiency of the mine. We found that it only takes a single broken machine to stop the whole workflow of the mine.

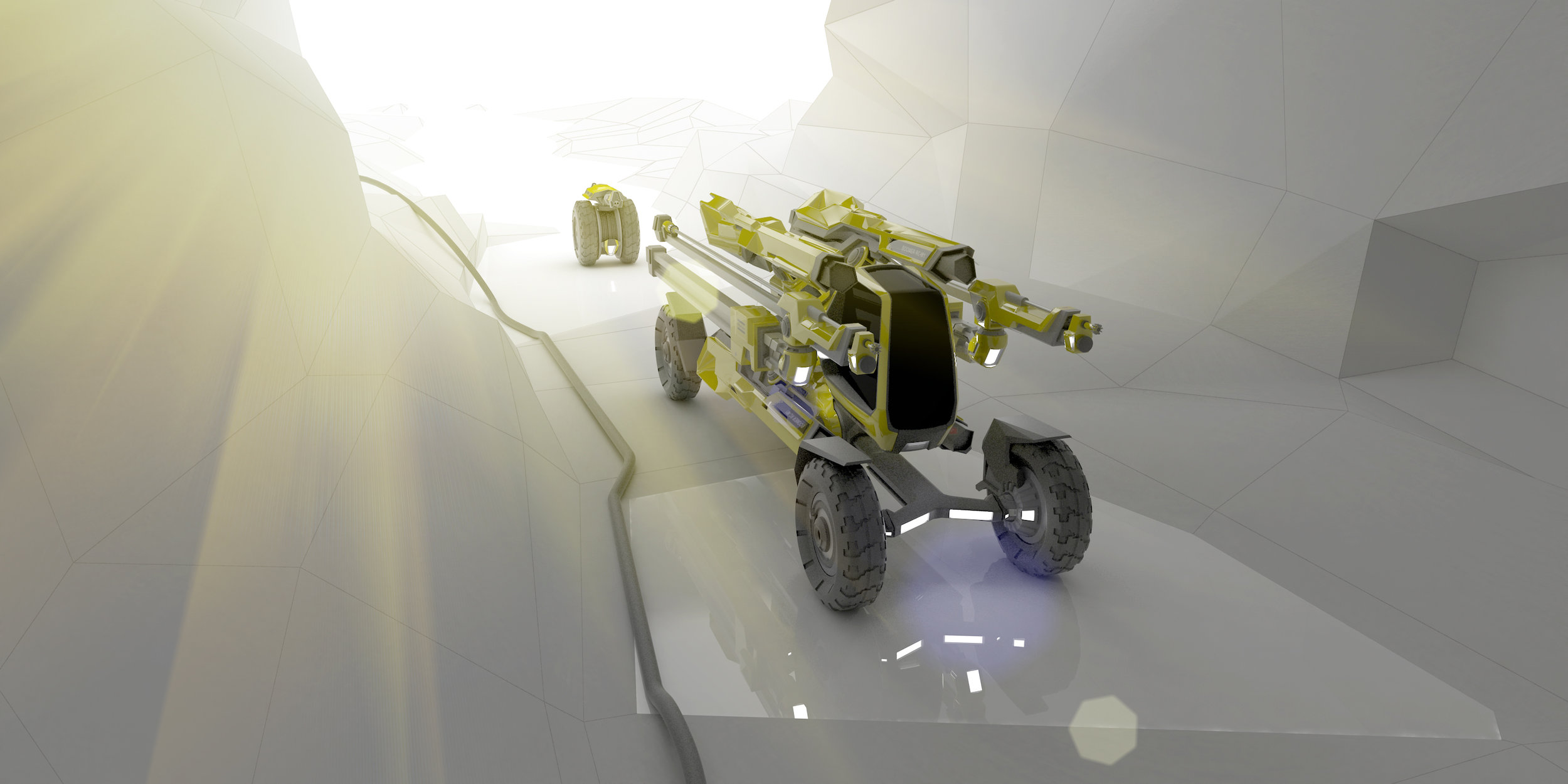

Flexibility to operate

The machine is compact during the mine maneuvering and the main module besides communicating the different parts, also facilitates the repositioning of the cabin during the work.

Inside the mine the ceiling is as strong as the floor, why not taking advantage of that to tackle more problems such as repositioning and safety getting the best visibility in every opportunity?

The cabin can detach from the machine to operate the machine from a safer place when the situation gets extreme.

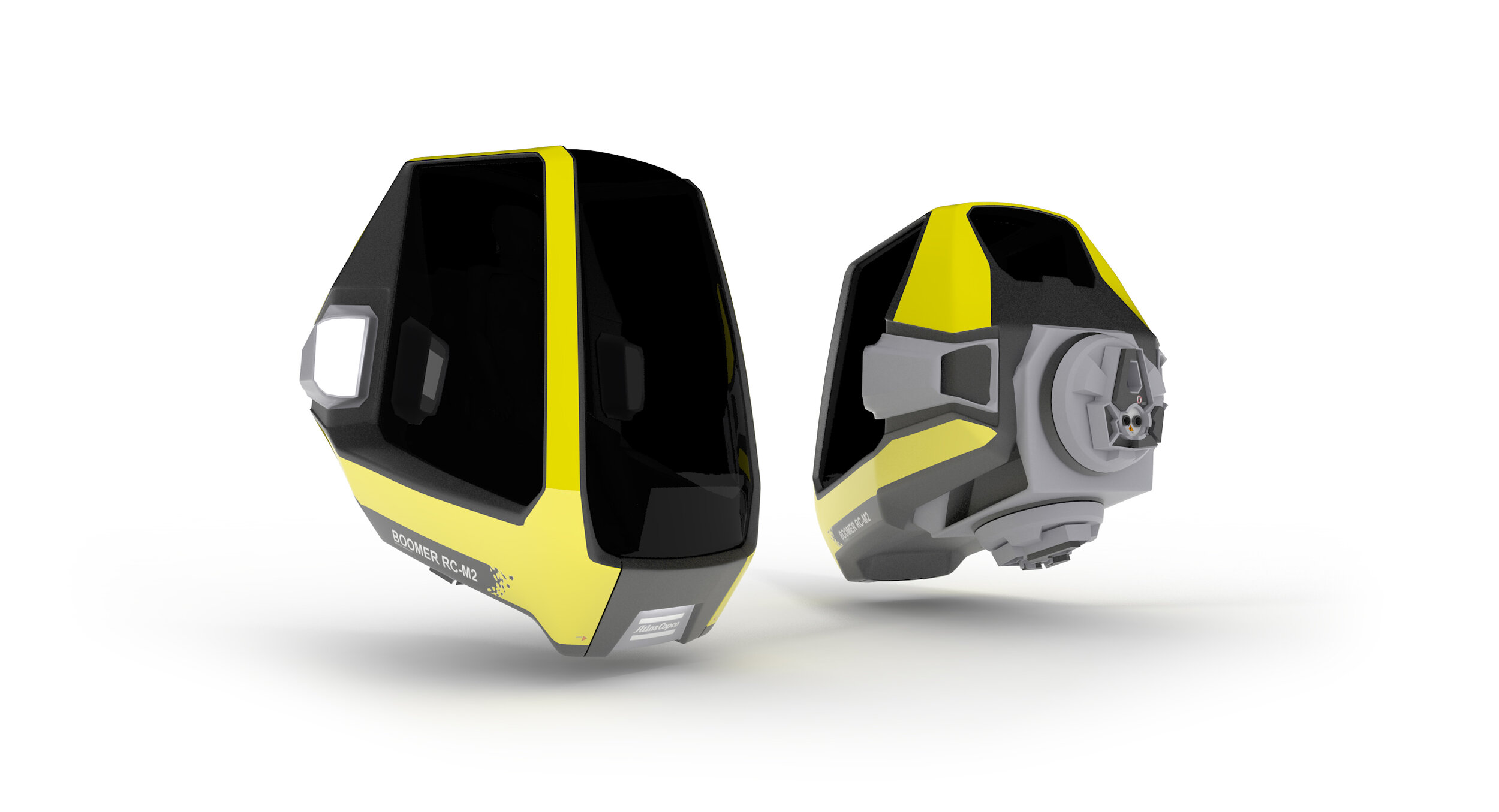

Main body module [ Detail ]

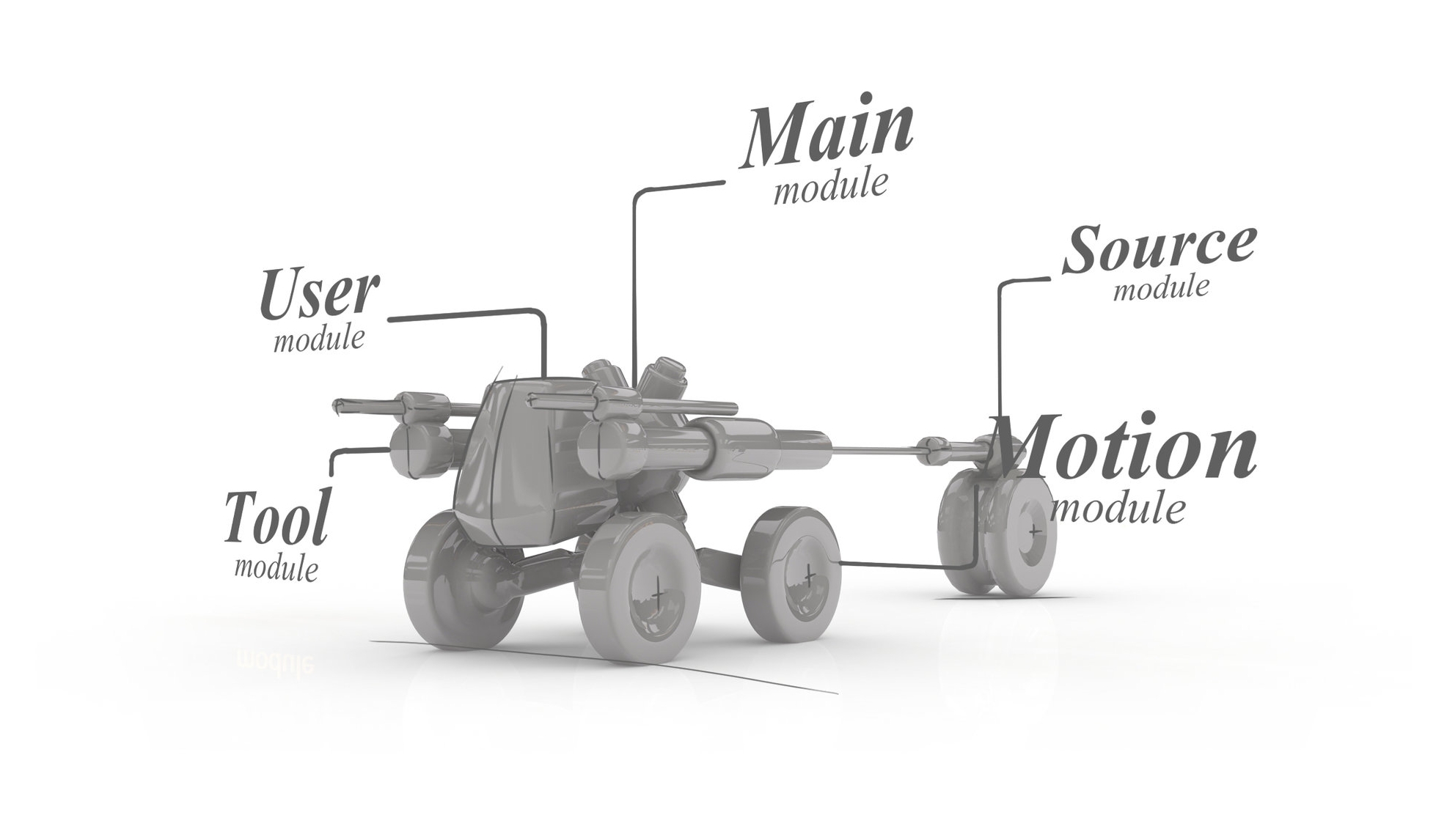

Vehicle Architecture

Splitting the machine in modular parts saves space in the workshop. Organizing the modules in dedicated maintenance areas it is easier and cheaper to combine, upgrade and repair the machine and its tools (drilling / bolting / scaling), offering the possibility to change the damaged module for an operational one on-site so the machine doesn’t stop working and the workflow is never interrupted.

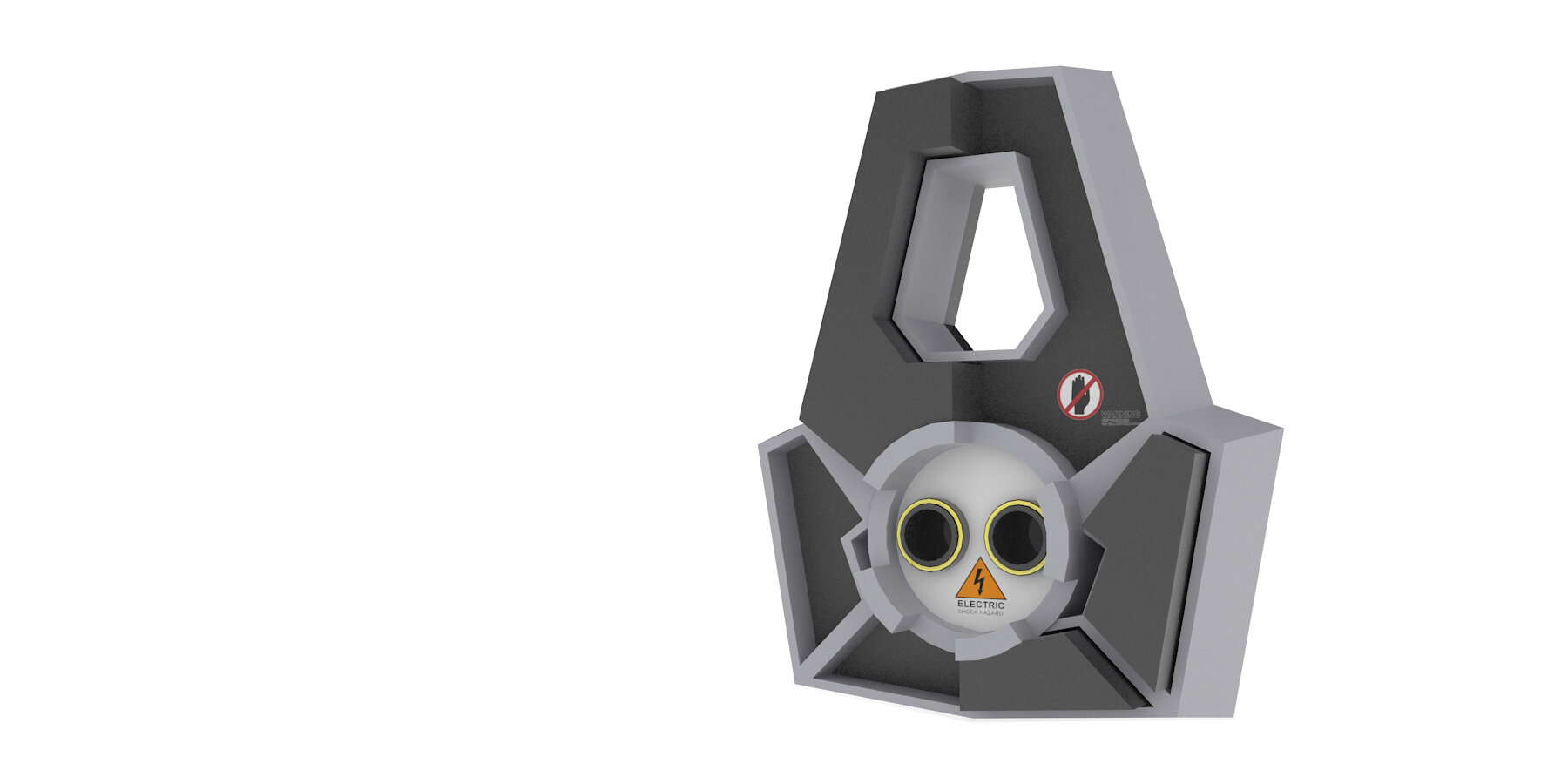

Proactive Workshop

An organized workshop is an efficient one. Dedicated areas per module would organize not just the workshop tooling but the times of repair and maintenance. Tools in the right place for the right thing and the possibility to send a repaired module to a machine site without stopping the mine operation is just one of the possible implications.